In today’s fast-paced industrial world, efficiency is crucial for staying competitive. The key to unlocking that efficiency lies in leveraging connected IoT HMI solutions. At Senzr, we’re redefining how industries monitor, control, and optimize their machines through an integrated ecosystem of smart HMI hardware, intelligent software, and cloud platforms.

By integrating IoT technology with HMI, industries can significantly enhance machine efficiency and transform their operations. This article will explore how Senzr’s ecosystem can help industries achieve this goal.

Key Takeaways

- Discover how connected IoT HMI can boost machine efficiency.

- Learn about Senzr’s integrated ecosystem for industrial automation.

- Understand the importance of efficiency in industrial settings.

- Explore the role of smart HMI hardware in optimizing machine performance.

- Find out how intelligent software and cloud platforms can enhance industrial operations.

The Industrial Revolution 4.0: Why Machine Efficiency Matters

As industries evolve with the Industrial Revolution 4.0, the importance of machine efficiency cannot be overstated. The drive towards greater productivity and competitiveness has made optimizing machine performance a top priority.

The Cost of Inefficiency in Modern Manufacturing

Inefficient machines can lead to significant losses in modern manufacturing, including increased energy consumption, higher maintenance costs, and reduced product quality. These inefficiencies can cumulatively affect a company’s bottom line and competitiveness in the market.

How Digital Transformation is Reshaping Industries

Digital transformation is revolutionizing industries by introducing advanced technologies such as IoT, AI, and data analytics. This transformation enables real-time monitoring and optimization of machines, leading to improved efficiency and reduced downtime.

The Role of Human-Machine Interfaces in Operational Excellence

Human-Machine Interfaces (HMIs) play a crucial role in achieving operational excellence by providing operators with real-time data and control capabilities. Connected IoT HMIs, in particular, enable real-time monitoring and optimization, enhancing overall machine efficiency and productivity.

Understanding Connected IoT HMI for Machines

Connected IoT HMI represents a significant advancement in industrial automation, enhancing machine efficiency and productivity. This integration of hardware, software, and cloud connectivity is revolutionizing the way machines operate and are managed.

Defining the Connected HMI Ecosystem

The connected HMI ecosystem is a complex interplay of various components that work together to provide a seamless operational experience. It encompasses several key elements:

Hardware Components and Touchpoints

These include the physical devices and interfaces through which operators interact with machines. Modern HMIs are equipped with advanced touchscreens and intuitive interfaces that simplify complex operations.

Software Intelligence and Processing

The software component brings intelligence to the HMI, enabling real-time data processing, analytics, and decision-making. This layer is crucial for transforming raw data into actionable insights.

Cloud Connectivity and Remote Access

Cloud connectivity allows for remote monitoring and control of machines, providing flexibility and enhancing operational efficiency. This feature is particularly valuable for industries with multiple locations or remote assets.

How Connected HMI Differs from Traditional Interfaces

Unlike traditional HMIs, connected IoT HMIs offer a more integrated and intelligent approach to machine management. They provide real-time data visualization, remote monitoring capabilities, and predictive maintenance alerts, significantly enhancing operational efficiency.

The Data-Driven Advantage in Machine Operations

The data-driven advantage is a key benefit of connected IoT HMIs. By leveraging real-time data and analytics, industries can optimize machine performance, reduce downtime, and improve overall productivity. This data-driven approach enables more informed decision-making and strategic planning.

| Feature | Traditional HMI | Connected IoT HMI |

|---|---|---|

| Real-Time Data | Limited | Extensive |

| Remote Monitoring | No | Yes |

| Predictive Maintenance | No | Yes |

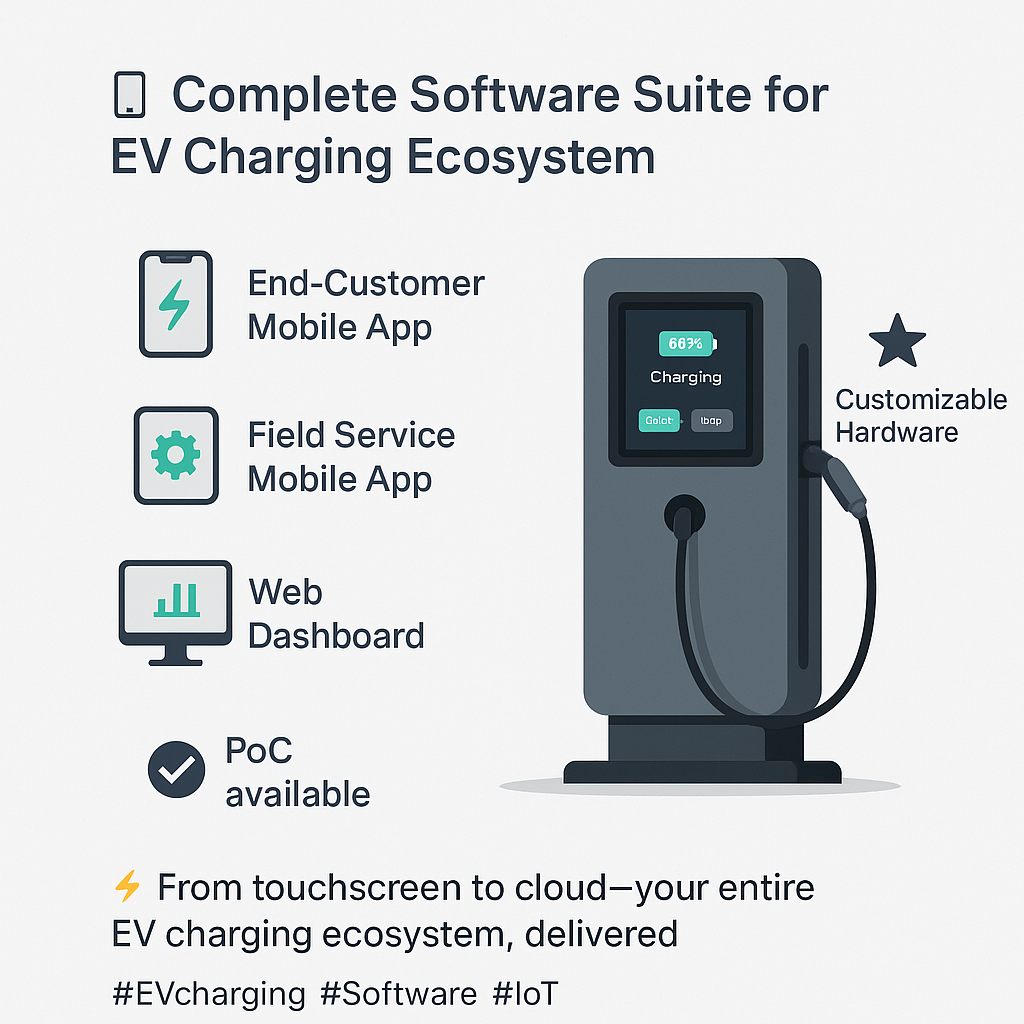

The Senzr Ecosystem: Integrated Hardware, Software, and Cloud

At the heart of Senzr’s innovative solution lies a comprehensive ecosystem that combines industrial-grade HMI hardware, intelligent software, and cloud capabilities. This integrated approach is designed to provide industries with a seamless and efficient way to connect their machines, monitor operations in real-time, and leverage data for predictive maintenance and improved productivity.

Overview of the Senzr Connected Solution

The Senzr connected solution is built around the concept of creating a highly interconnected and intelligent industrial environment. By integrating hardware, software, and cloud services, Senzr enables manufacturers to achieve a higher level of operational efficiency and responsiveness.

Key Components Working Together

The effectiveness of the Senzr ecosystem is rooted in its key components, which work in harmony to deliver a robust and scalable solution.

Industrial-Grade HMI Hardware

The industrial-grade HMI hardware provided by Senzr is designed to withstand the rigors of industrial environments while offering a user-friendly interface for operators. This hardware is crucial for capturing data from machines and providing real-time insights.

Intelligent Software Layer

The intelligent software layer is the brain of the Senzr ecosystem, enabling advanced data analysis, local logic execution, and automated alerts. This layer is pivotal in turning raw data into actionable insights.

Cloud Platform Capabilities

Cloud platform capabilities allow for the storage, processing, and analysis of large datasets, facilitating remote monitoring and control. The cloud infrastructure is scalable and secure, ensuring that data is protected and accessible as needed.

Seamless Integration with Existing Infrastructure

One of the key strengths of the Senzr ecosystem is its ability to integrate seamlessly with existing infrastructure. This ensures that manufacturers can adopt the Senzr solution without significant disruptions to their operations, making the transition to a more connected and efficient factory floor smoother.

SenzrOS: The Intelligent Operating System for Industrial HMI

At the heart of modern industrial HMI lies SenzrOS, an intelligent operating system that is transforming machine efficiency. SenzrOS is designed to provide a robust foundation for industrial automation applications, leveraging advanced technologies to enhance performance and reliability.

Lightweight Design for Edge Computing

SenzrOS boasts a lightweight design that is optimized for edge computing, enabling faster data processing and reduced latency. This design ensures that critical data is processed in real-time, closer to where it’s generated, thus improving overall system responsiveness.

Real-Time Data Processing Capabilities

One of the key features of SenzrOS is its ability to process data in real-time. This capability is crucial for industrial applications where timely decision-making is essential. By processing data at the edge, SenzrOS reduces the need for constant cloud connectivity, enhancing operational efficiency.

Secure Communication Protocols

SenzrOS incorporates secure communication protocols to safeguard data exchange between devices and systems. These protocols ensure that industrial operations remain secure and compliant with relevant standards, protecting against potential cyber threats.

Plug-and-Play Integration Features

The plug-and-play integration feature of SenzrOS allows for seamless connectivity with existing infrastructure, minimizing the need for extensive reconfiguration or additional hardware. This flexibility makes it easier for industries to adopt and integrate SenzrOS into their operations.

By combining a lightweight design, real-time data processing, secure communication, and plug-and-play integration, SenzrOS sets a new standard for industrial HMI operating systems. Its capabilities are poised to significantly impact industrial automation, driving efficiency and innovation.

Real-Time Monitoring and Control Capabilities

Real-time monitoring and control capabilities are at the forefront of optimizing machine performance in the industrial sector. By leveraging connected IoT HMI solutions, industries can significantly enhance their operational efficiency.

Sensor Data Capture and Visualization

One of the key features of connected IoT HMI is its ability to capture and visualize sensor data in real-time. This allows operators to monitor machine performance closely and make informed decisions. Effective data visualization is crucial for quickly identifying trends and anomalies.

Local Logic Execution and Automated Alerts

Connected IoT HMI solutions enable local logic execution, allowing for immediate responses to changes in machine status. Automated alerts notify operators of potential issues, ensuring prompt action can be taken to prevent downtime.

Remote Monitoring and Control Functions

The ability to monitor and control machines remotely is a significant advantage of connected IoT HMI. This feature provides operational flexibility, enabling industries to respond to issues even when personnel are not on-site.

Predictive Maintenance Applications

Predictive maintenance is a critical application of real-time monitoring and control capabilities. By analyzing data from connected machines, industries can predict when maintenance is required, reducing the likelihood of unexpected downtime. As noted by industry experts, “Predictive maintenance is not just about reducing costs; it’s about creating a more efficient and responsive manufacturing process.”

“The future of manufacturing lies in its ability to adapt and evolve through technology like connected IoT HMI.”

By embracing real-time monitoring and control capabilities, industries can achieve significant improvements in machine efficiency and overall productivity.

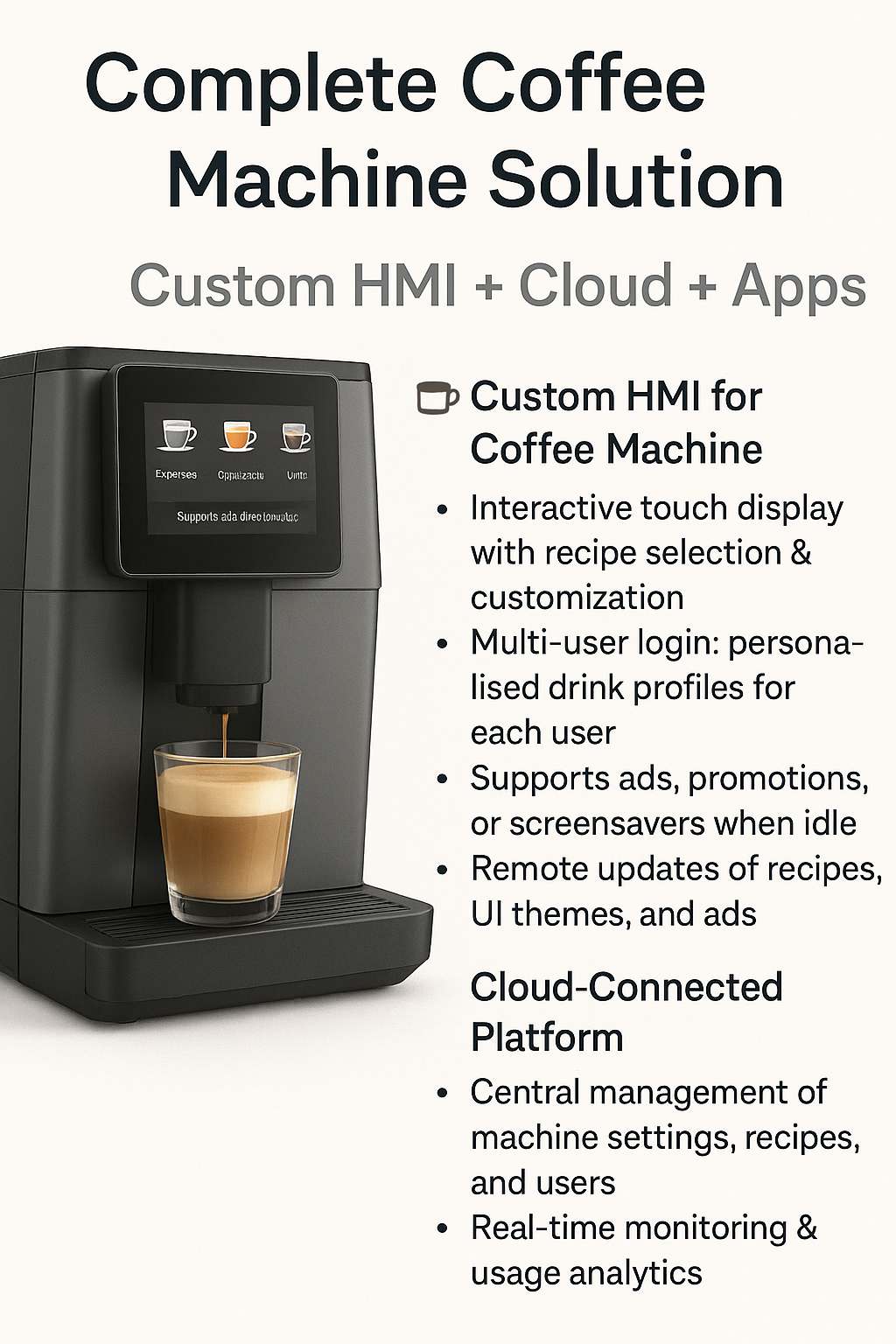

White-Labeled IoT Cloud Solutions for OEMs

White-labeled IoT cloud solutions are revolutionizing the way OEMs deliver IoT services to their customers. By adopting these solutions, OEMs can offer customized and scalable IoT connectivity that enhances their brand value.

Customizable Branding Opportunities

OEMs can leverage white-labeled IoT cloud solutions to create tailored IoT services that align with their brand identity. This includes customizable user interfaces and branded mobile apps, ensuring a seamless customer experience.

Scalable Architecture for Various Applications

A scalable architecture is crucial for IoT solutions, allowing them to adapt to growing demands and new applications. White-labeled IoT cloud solutions provide this scalability, enabling OEMs to expand their IoT offerings without significant infrastructure investments.

API Integration and Development Tools

API integration is a key feature of white-labeled IoT cloud solutions, facilitating the development of customized IoT applications. OEMs can utilize these APIs to integrate their existing systems with the IoT cloud, enhancing operational efficiency.

Deployment and Management Options

White-labeled IoT cloud solutions offer flexible deployment options, including cloud, on-premise, or hybrid models. This flexibility allows OEMs to choose the deployment strategy that best suits their business needs, ensuring efficient management and maintenance of their IoT solutions.

As stated by a leading industry expert,

“The future of IoT lies in customized and scalable solutions that meet the specific needs of businesses.”

White-labeled IoT cloud solutions are poised to drive this future, empowering OEMs to deliver innovative IoT services.

Implementation Roadmap: From Concept to Connected Factory

A well-planned implementation roadmap is crucial for the successful adoption of connected IoT HMI technologies. This roadmap guides manufacturers through the process of transforming their operations into a connected factory, where machines and systems are fully integrated and optimized.

Assessment and Planning Phase

The first step in implementing a connected IoT HMI solution is the assessment and planning phase. This involves:

- Identifying Key Machines and Processes: Manufacturers must determine which machines and processes are critical to their operations and will benefit most from being connected.

- Setting Performance Metrics and Goals: Clear performance metrics and goals must be established to measure the success of the implementation.

Identifying Key Machines and Processes

This step involves analyzing the current state of machinery and processes to identify areas where connectivity can have the most significant impact.

Setting Performance Metrics and Goals

Establishing clear metrics and goals allows manufacturers to measure the effectiveness of their connected IoT HMI solution and make data-driven decisions.

Deployment and Integration Strategies

A well-planned deployment strategy ensures that the connected IoT HMI solution is integrated seamlessly with existing systems and infrastructure.

Training and Change Management

Effective training and change management are critical to ensuring that personnel are equipped to maximize the benefits of the connected IoT HMI solution.

Measuring ROI and Performance Improvements

Finally, manufacturers must measure the return on investment (ROI) and performance improvements achieved through the connected IoT HMI solution. This involves ongoing monitoring and analysis to identify areas for further optimization.

Case Studies: Smart Machines IoT Success Stories

Industries are witnessing a paradigm shift with the adoption of smart machines IoT. This transformation is evident across various sectors, with the manufacturing industry being one of the primary beneficiaries.

Manufacturing Sector Transformation

The integration of smart machines IoT in manufacturing has led to significant improvements in operational efficiency. Efficiency gains and downtime reduction are among the key benefits observed.

Efficiency Gains and Downtime Reduction

A notable case study involves a leading automotive manufacturer that implemented smart machines IoT. They achieved a 25% increase in production efficiency and a 30% reduction in downtime within the first six months.

Quality Improvement Metrics

Quality improvements were also significant, with a reduction in defect rates by 20%. This was largely due to real-time monitoring and predictive maintenance enabled by IoT technologies.

Energy Management Optimization

Smart machines IoT has also played a crucial role in optimizing energy management. By leveraging IoT sensors and real-time data analytics, companies have been able to reduce energy consumption and lower operational costs.

| Industry | Energy Savings | Cost Reduction |

|---|---|---|

| Manufacturing | 15% | $100,000 annually |

| Logistics | 10% | $50,000 annually |

Supply Chain and Logistics Enhancements

The adoption of smart machines IoT has also enhanced supply chain and logistics operations. Real-time tracking and predictive analytics have improved delivery times and reduced logistical costs.

Conclusion: Embracing the Future of Connected Machine Efficiency

As industries continue to evolve towards greater connectivity and automation, embracing connected machine efficiency is crucial for remaining competitive. By leveraging connected IoT HMI solutions like Senzr, industries can unlock new levels of productivity, efficiency, and innovation.

The future of industrial automation is connected, intelligent, and efficient. With the integration of advanced technologies, industries can optimize their operations, reduce costs, and improve product quality. Connected machine efficiency is no longer a luxury, but a necessity for industries to thrive in the modern manufacturing landscape.

By adopting connected IoT HMI solutions, industries can stay ahead of the curve and capitalize on the benefits of the future of industrial automation. As the manufacturing landscape continues to evolve, it’s time for industries to embrace the power of connected machine efficiency and shape the future of industrial automation.